Industrial touch panel PCs play a crucial role in the context of industrial machinery for several reasons:

Industrial touch panel PCs play a crucial role in the context of industrial machinery for several reasons:

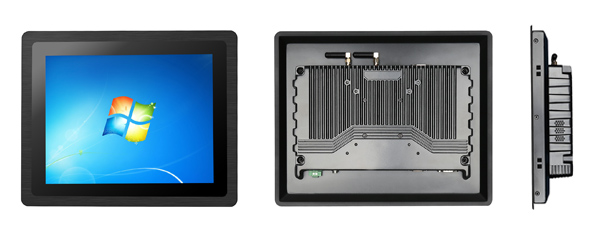

Robustness and Durability: Industrial touch panel PCs are specifically designed to withstand the harsh conditions of harsh or hazardous industrial environments. They are built to resist dust, water, vibrations, extreme temperatures, oil & chemicals, and electromagnetic interference. Usually, industrial panel PCs are designed with front IP65-rated. Their rugged construction design ensures 24/7 reliable operation even in challenging settings, their chassis materials include plastic, stain steel, and aluminum alloys, and aluminum alloy housing panel PCs have a good heat-dissipation performance, which is very important for stable operation. All these features are critical for industrial machinery's running when they are equipped with industrial touch panel PCs as their display panels and computing center because these industrial machinery are usually installed on manufacturing floors or outdoor installations.

Human-Machine Interface (HMI): Industrial touch panel PCs provide a user-friendly interface for operators to interact with industrial machinery. Through the touch screen, operators can monitor machine parameters, control operations, input commands, and visualize real-time data. This intuitive HMI enhances productivity, simplifies machine control, and reduces the learning curve for operators. Usually, for industrial machinery, 7" to 24" are popular display sizes, because this range of display sizes are providing suitable viewing angles for most sizes of machinery.

Real-time Monitoring and Data Analysis: Touchscreen panel PCs enable real-time monitoring of critical parameters, such as temperature, speed, pressure, and various production and operation metrics. Operators can instantly identify any abnormalities or deviations from set parameters, allowing for prompt corrective actions. Moreover, these panel PCs often have built-in data acquisition capabilities and can store and transmit data to higher-level systems for analysis, optimization, and predictive maintenance. This function is critical in the digital factory's automated production system.

Integration and Connectivity: These industrial panel PCs offer various I/O connectivity options to interface with different industrial machinery and equipment. And these I/Os are customizable to meet different requirements. They can connect to programmable logic controllers (PLCs), sensors, motors, and other devices, enabling seamless integration into the overall automation system. This integration facilitates data exchange, synchronization, and coordinated control of multiple machines, enhancing overall efficiency.

Customization and Flexibility: Industrial touch panel PCs can be customized to meet specific requirements of different industrial machinery. They can be tailored to support specialized protocols, communication interfaces, and software applications relevant to the machinery's operation. This flexibility allows for seamless integration with existing systems and provides the ability to adapt to changing industrial needs. What's more, industrial panel PCs can be customized in other aspects including a wide temperature range operation (-30 to +80 Celsius degree), wide voltage operation (9~36V), screen performance (high nits, anti-glare, full viewing angles, etc.), logo, and functional modules (camera, RFID, NFC, face recognition, temperature measuring, etc.).

Remote Access and Control: Some industrial touch panel PCs offer remote access capabilities, enabling authorized personnel to monitor and control machinery from a central location. Remote access allows for troubleshooting, software updates, and diagnostics without the need for physical presence at the machine site. This feature reduces downtime, enhances maintenance efficiency, and improves overall productivity.

Safety and Compliance: Industrial machinery often needs to adhere to strict safety regulations and standards. Industrial touch panel PCs can incorporate safety features, such as emergency stop buttons, lockout/tagout controls, and visual indicators for hazardous conditions. They can also provide access control and user authentication to prevent unauthorized operation or tampering. This kind of industrial touch panel PC is often used in workstations of MES systems in factories.

In summary, industrial touch panel PCs are vital components in industrial machinery as they provide a robust, user-friendly interface for machine control, data visualization, and monitoring. They enhance productivity, facilitate integration with automation systems, ensure compliance with safety regulations, and enable efficient maintenance and troubleshooting.