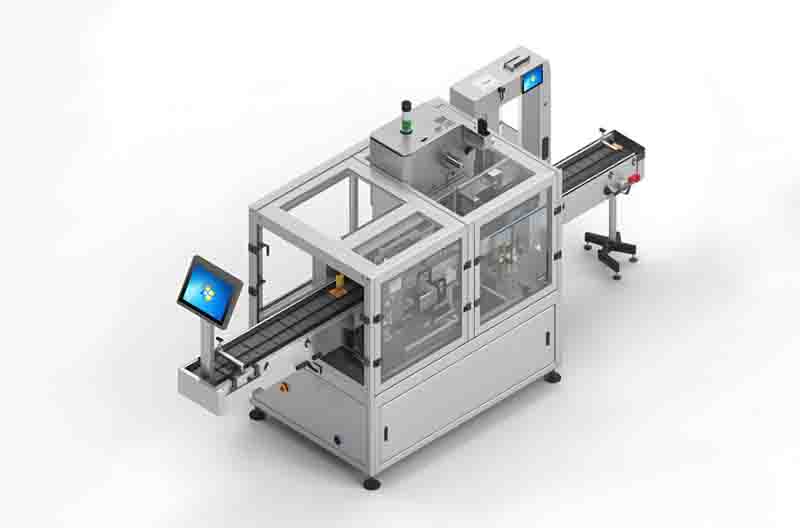

In today’s intelligent manufacturing era, industrial packaging equipment plays a vital role in ensuring productivity, accuracy, and quality. From filling and sealing to labeling and inspection, every step relies on precise automation.

At the heart of these systems lies the Industrial Panel PC — a powerful Human-Machine Interface (HMI) that integrates display, control, and data management into one compact and durable device.

The Role of Industrial Panel PCs in Packaging Equipment

1. HMI and Central Control

An Industrial Panel PC acts as the operator interface for real-time monitoring and control. Through its touchscreen display, operators can easily:

✅ Adjust machine parameters such as speed, temperature, or sealing pressure;

✅ Start or stop the packaging line;

✅ Monitor production counts and performance data;

✅ Review alarm logs and system history.

The intuitive interface simplfies complex operations, reducing downtime and operator error.

2️. Data Collection and Communication

Equipped with versatile industrial interfaces such as RS-232/422/485, Modbus, Profinet, CAN bus, and Ethernet, the panel PC communicates seamlessly with PLCs, sensors, and servo drives.

It enables:

✅ Real-time collection of production data (speed, weight, temperature, humidity);

✅ Data transmission to MES/ERP systems or cloud platforms for smart manufacturing management;

✅ Centralized control and performance tracking across the entire packaging line.

3. Automation and Intelligent Control

By integrating the Industrial Panel PC with machine control systems, manufacturers can achieve advanced automation such as:

- Automatic feeding, sealing, and labeling;

- Multi-station synchronization and coordination;

- Automatic fault detection and alarm response;

- AI-powered or vision-based inspection for label accuracy and defect detection.

This enhances both precision and productivity in modern packaging systems.

4. Remote Monitoring and Maintenance

Modern Industrial HMIs support remote access and IoT connectivity. Engineers can:

✅ Monitor machine status in real time from anywhere;

✅ Update software or troubleshoot remotely;

✅ Perform predictive maintenance to reduce unplanned downtime.

This capability helps ensure continuous operation and higher equipment uptime.

⚙️ Typical Installation Points

Equipment Type

| Installation Position | Main Function |

| Filling Machine | Front control panel

| Adjust filling volume, display flow and pressure |

| Labeling Machine | Beside labelling head | Set label position, synchronize speed |

| Vertical Packaging Machine | Front or side panel | Control sealing, film rolling, and cutting |

| Cartoning Machine | Inside control cabinet | Coordinate robotic picking and packing |

| Vision Inspection Line | Central console | Display inspection results and defect images |

�� Why Choose an Industrial Panel PC?

| Feature | Industrial Panel PC | Standard Computer |

| Protection Level | IP65/IP66 dust and waterproof | No industrial protection |

| Operating Temperature | -20°C ~ 60°C, 24/7 operation | Limited to office environments |

| Connectivity | Multiple serial ports, LAN, GPIO, CAN | Limited interfaces |

| Mounting Options | Embedded, wall-mounted, desktop stand, or VESA | Desktop only |

| Durability | Industrial-grade components, anti-vibration | Consumer-grade compnents |

Applications Across Packaging Industries

◆ Food and beverage packaging automation systems

◆ Pharmaceutical and cosmetic packaging lines

◆ Electronic component anti-static packaging solutions

◆ Daily chemical labeling and boxing systems

◆ Smart packaging inspection and barcode verification

Conclusion: The Central Brain of Smart Packaging Systems

The Industrial Panel PC is more than just a control terminal — it’s the intelligent hub of the modern packaging line.

With its powerful processing, rugged reliability, and intuitive interface, it connects people, machines, and data seamlessly.

By integrating an Industrial Panel PC, manufacturers can achieve:

✅ Real-time production visibility

✅ Rapid fault response

✅ Data traceability and performance analytics

✅ Smarter, more efficient packaging operations