PCs for Distributed Process Control

In the last several years, industrial pc has become an important part of control engineering. A wide variety of reliable hardware is available at relatively low cost, both in the PCs themselves and in peripherals. Up to now, however, they have been used mainly for monitoring small numbers of data points and for relatively simple process control applications. In general, PC hardware is quite sophisticated and capable of much more complex applications, but the software often used with PCs isn't powerful or fast enough to take full advantage of the hardware's capability. Often the PC is considered to be solely a DOS-based machine, when in fact DOS is not necessary, or can be coresident in memory.

Complex Process Control

There are many reasons to use PCs in a complex process control application besides the obvious cost advantage in the initial hardware purchases. If the hardware can be kept small and simple, the cost of housing it on the factory floor and providing power and cooling is reduced. Simple hardware tends to be more reliable, just because of the lower parts count. Programming the PCs and peripherals with powerful and efficient software gains several additional advantages.

Efficient software is that which maximizes the use of the hardware and also is small in both source and object code. Small size pays off in some less obvious areas in addition to the reduced hardware requirements. The code takes less time to develop; it is substantially easier to maintain; and it has inherently higher reliability, simply because of its size. Monitoring and Control Forth, Inc., has recently developed a distributed, real-time factory monitoring and control system incorporating the above principles, called the "PC Factory Network." It can monitor and control thousands of points, has a reliable multichannel communication protocol between processors, and can display process variables in multiple, concurrently-updating windows on the same CRT screen. It uses off-the-shelf microcomputer hardware, the polyFORTH operating system programming language instead of mainframes and minis and BASIC or C.

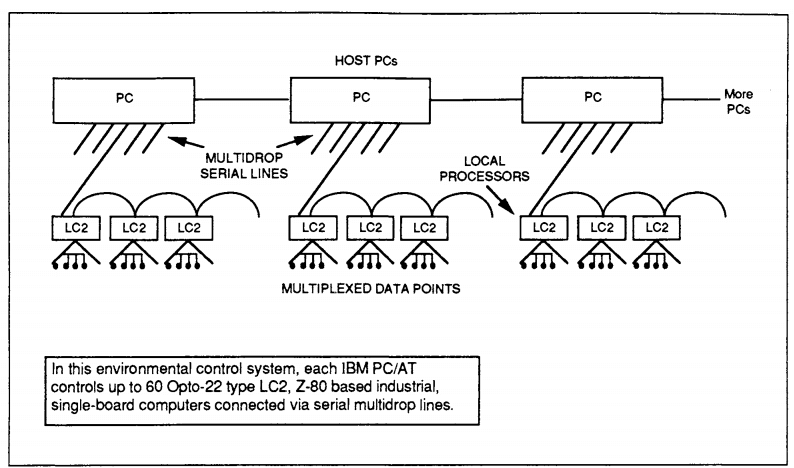

Versions of this system have been installed at a number of major industrial manufacturing companies. One recent example is an environmental control system featuring four IBM PC/ATs, each of which controls up to 60 LC2s monitoring temperatures and controlling heaters, chillers, and fans. A typical network consists of one or more IBM-ATs connected via serial lines to multiple local processors, which are Z80-based, Opto-22 type LC2 industrial, single-board computers. The LC2s are, in turn, serially connected to Opto-22 multiplexers and standard Opto-22 industrial I/O modules to perform monitoring and control of the plant floor data points. The local processor operation can be either autonomous or under control of the master PCs. PolyFORTH, a real-time, multitasking operating system, is used in both the PCs and the local LC2 processors.

Software

Besides collecting data, or reading data, from the process control system, the software must permit the user to safely conduct supervisory control. The user must be able to change setpoints, turn pumps on and off, and even reconfigure many of the control system's parameters, all from the PC. Since direct control is the responsibility of the process control system, the software must only allow specified users the privilege of conducting permissible supervisory control tasks, with lockouts to specified addresses within the control

system.

The software must be able to talk or communicate to many different control and data acquisition devices. Distributed control systems, programmable controllers, machine tools, robotics, operator entry terminals, and bar scans are several such devices that contain valuable process information. The software must be able to simultaneously communicate with many of these devices to ensure a complete database of process and time and attendance information. The database generated by the software must be usable by many, whether they be production operators, production supervisors, engineering and maintenance, or management. The software must be easily accessible to management information systems personnel for integration into higher-level computer planning requirements systems.

Since the user's primary responsibilities lie in production and not in computer programming, the software must be reliable. Configuration must be quick and simple; turn it on, and walk away to perform other required tasks. The hardware used must be reliable, inexpensive, and easily purchased. The personal or industrial computer operating under PC-DOS must be the reliable hardware and operating system standards used with the software. The operator must also be able to use the PC for additional tasks whether they be the programming of the control system or word processing; therefore, the software must multitask, with communications and building the database as a background task, while foreground tasks include real-time or historical analysis with graphics and spreadsheets, report generation, and other user-designated tasks.

User-friendly software is more than a must. Besides the software's fill-in-the-blanks approach, documentation must be clearly written and completely usable. The software must be enhanced with resident experts who can be easily contacted by telephone to answer numerous questions regarding such broad-based subjects as cabling, logging strategies, special spreadsheet requirements, and networking. If required, the software documentation and telephone support must be augmented with user training that provides support to all user levels.

The software must grow with the marketplace and, in some respects, must lead the market by the addition of new functionality and applications. As new PC hardware and operating systems are introduced, the software must be upward compatible. The user must be assured that the software will grow with the company's automation program. For many applications, the software must function as the cornerstone of an integrated and fully-distributed manufacturing information system. The software must provide, through any number of floor-level workstations, operator interface, data collection and storage, and passage of data to higher supervisory levels and to higher-level mini and mainframe computers as a truly distributed CIM system.